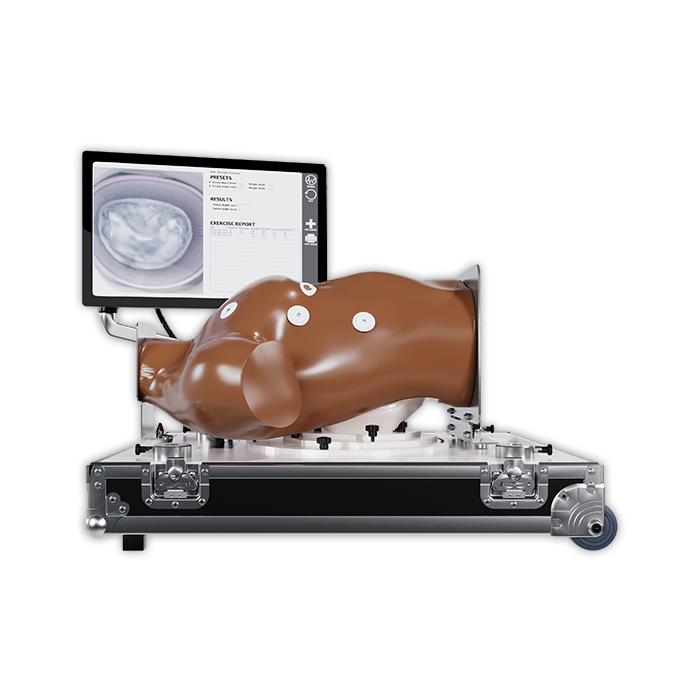

Training for particularly complex pathology or preparing for minimally invasive procedures can have a distinct time-sensitive character. This can be a mismatch with waiting for

patient-specific 3D printed Tactile Anatomy for use in your Simurghlator or stand-alone application to be printed and shipped from our facilities. Based on a rising number of customer

requests, Simurghy created a solution that enables you to conveniently recreate patient anatomy in our unique material options yourself.

Integral Solution

Tactile Anatomy Creator offers a end-to-end process. It contains advanced 3D modeling and customized print preparation software, an industry grade 3D printer, specific 3D print materials as well as post-processing automation hardware.

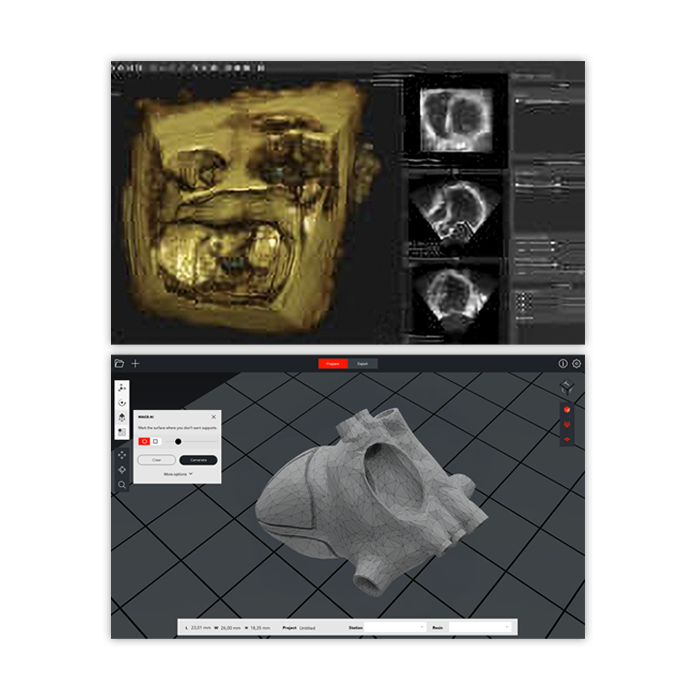

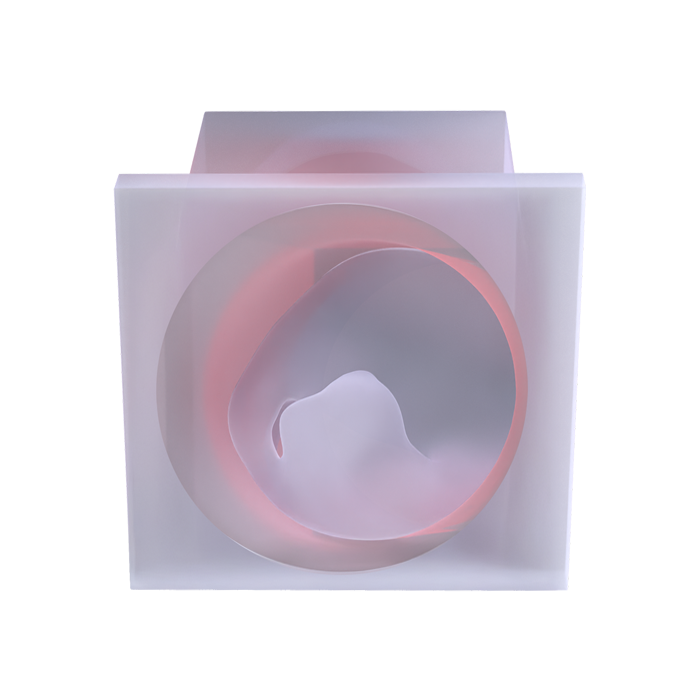

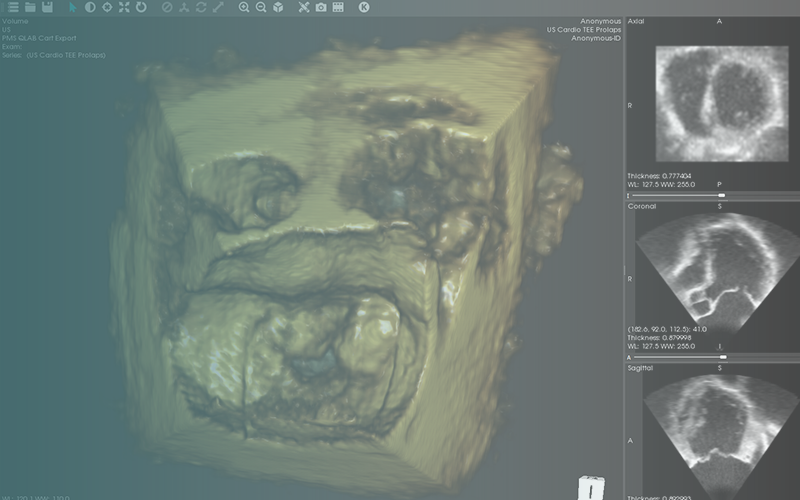

Multiple Inputs

The included state-of-the-art 3D modeling software can create interactive 3D Tactile Anatomy model files based on CT, MRI or Echo data. While user-friendly, it includes advanced tools to make arbitrary extractions and optimizes 3D mesh data for printing.

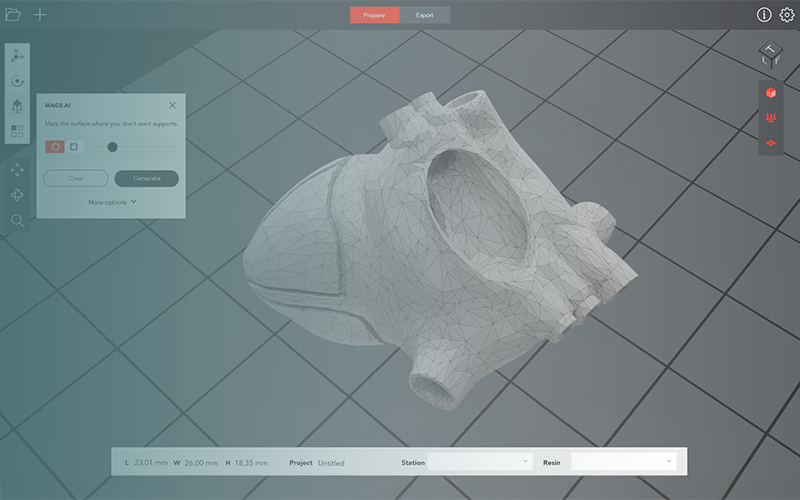

Optimized Workflow

Both the included 3D modeling software and print job preparation software have been integrated to ensure an easy workflow to translate scanner data to a print job. It only takes a few clicks to model and export patient-specific Tactile Anatomy for print.

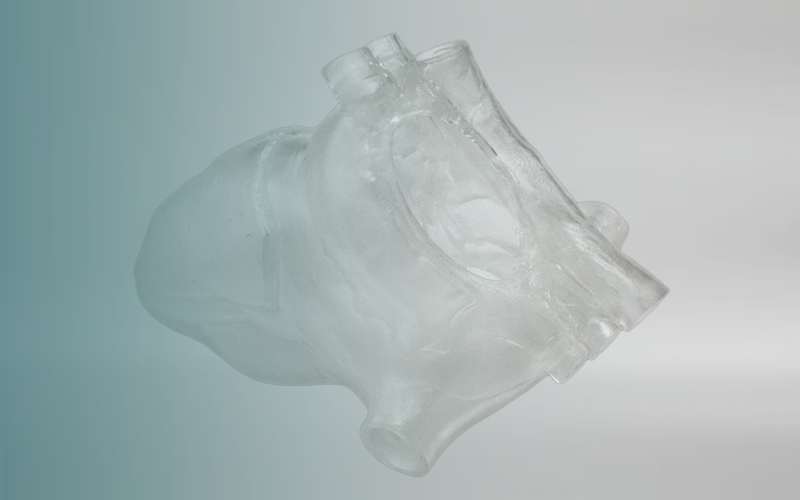

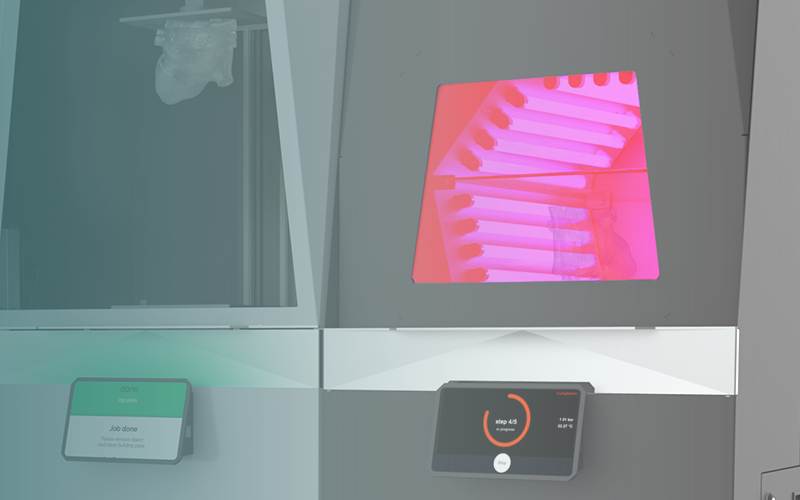

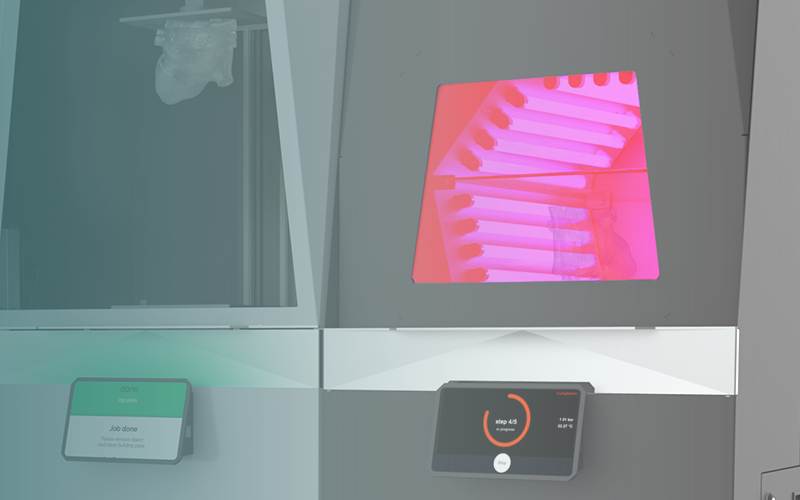

Fast, Efficient & Accurate

Our Tactile Anatomy Creator 3D printer is among the fastest available. Its Digital Light Processing (DLP) technology accurately solidifies liquid resin using UV light. The large capacity enables creating multi-model prints, often without impacting print duration.

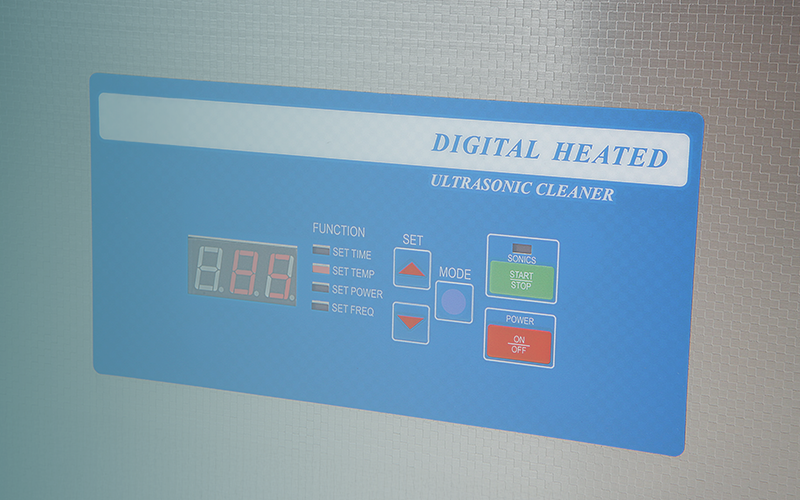

Automated Post-Processing

Once the models have been printed, a couple of additional steps are required to achieve the final material properties. Tactile Anatomy Creator includes the tools to speed up and largely automate the cleaning and post-curing the printed Tactile Anatomy models.